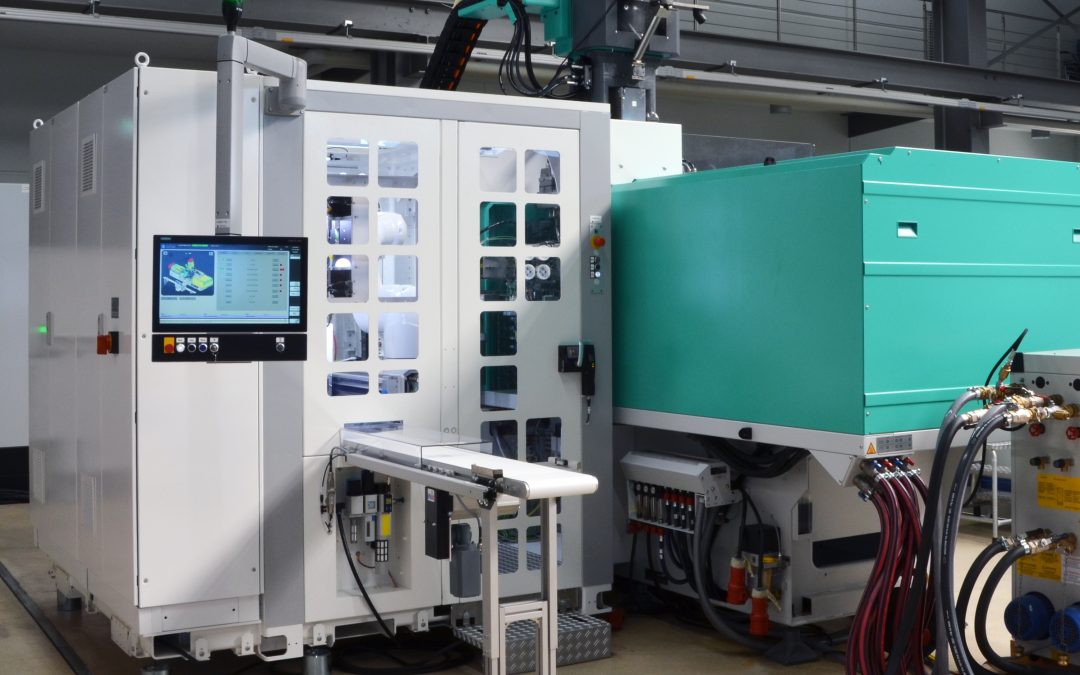

Below the topic “We automate molds,” ZAHORANSKY Automation & Molds GmbH will present its comprehensive solutions for manufacturing systems of plastic-based medical products at the Fakuma 2024 in Friedrichshafen. Whether it’s primary packaging such as pre-filled syringes or vials, systems for drug delivery, or dialysis device components: based on decades of experience in machine and mold making, plastics technology, and automation, ZAHORANSKY offers its customers comprehensive solutions for the production of complex plastic, hybrid, and glass replacement products. While manufacturers usually need to work with various machine and mold makers and other service providers to assemble their production line, ZAHORANSKY provides everything from a single source – from consultation and product design to the development and manufacturing of injection molds, and finally, the design and installation of highly automated No-Human-Touch production systems in modular construction. Visitors at the Fakuma (Hall A2, Booth 2309) can learn how this approach can lead to greater implementation, planning, and process reliability, increase overall equipment effectiveness, and reduce unit costs as well as personnel and resources.

A recent example is an automation solution developed by ZAHORANSKY, including an innovation internal mold handling for the two-component injection molding of applicator closure caps for digital diabetes sensors. The compact system, with minimal mold opening and a high degree of automation, leads to increased output and process reliability while significantly saving space and costs.

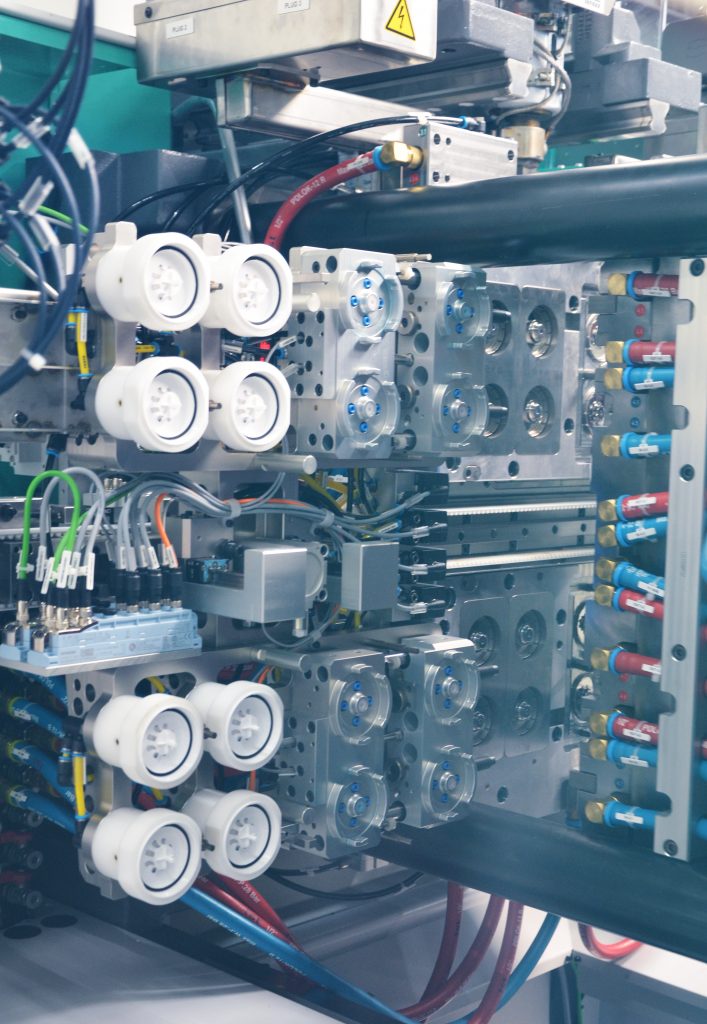

In realizing the customer-specific solution for the highly automated production of applicator closure caps using two-component injection molding, the thread of the cap presented a challenge – it needed to be unscrewed rather than simply ejected from the mold. Additionally, the customer requested a compact system with a high degree of automation for mass production due to space constraints. For this tailored solution, ZAHORANSKY employed the “Z.WARP move” mold, featuring an innovation in internal mold handling: while the freshly molded base component is removed by an integrated automated handling unit, the pitch dimension can be compressed before the semi-finished product is placed for the second component. This way, the distances between the cavities are optimally set for the subsequent injection molding process. The finished caps are then removed parallel to the injection molding process by a six-axis robot. The innovative process offers the customer several advantages: in addition to a significantly shorter cycle time, the minimal mold opening results in significant space and cost savings, as the associated injection molding machine can also be considerably smaller and thus less expensive due to the well-thought-out design.

In addition, the Z.SIROC automation module is used for quality control: the finished caps are presented to the six-axis robot directly to the camera in the automation cell, where they are measured, inspected, and either sorted out or passed on for further processing. This minimizes the effort required by employees and ensures that good and defective parts are not mixed.